MODERNISATION OF MACHINES

KEY CONCEPTS FOR EQUIPMENT UPGRADES

The retrofitting of metalworking machines is carried out in our factory in Berlin.

The main concept of modernisation is the use of high-quality components from leading manufacturers such as Siemens, Rexroth, Parker, Hawe, Lapp, Igus, RSF, Sauter, Flender, etc.

Strict quality control is carried out at all stages of the modernisation:

- complete dismantling of the machine;

- compilation of the list of defects;

- repair and replacement of wear parts;

- fine milling and subsequent scraping of the guide rails;

- revision and repair of the gearbox;

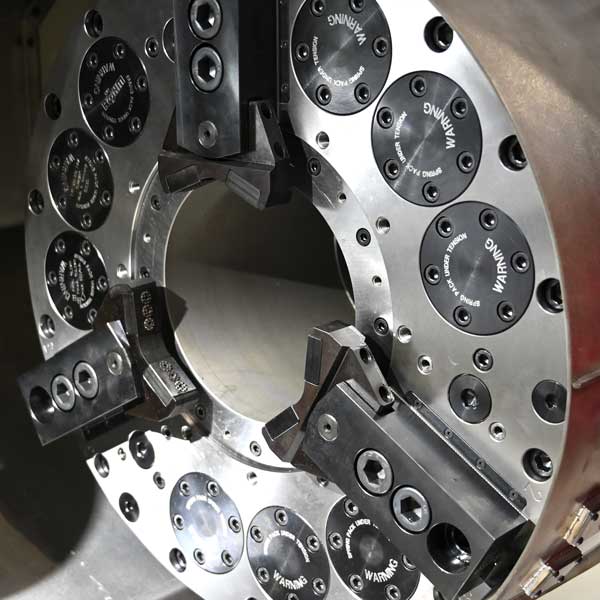

- restorative repair of spindles;

- replacement of the ball screw;

- Revision and repair of tool changer and tool clamping and locking devices;

- Refurbishment of machine electrical systems, control cabinets and control panels according to VDE regulations;

- Repair and adjustment of hydraulic, pneumatic and lubrication systems;

- Painting of the machine and its parts.

Technical retooling is a continuous process, the discontinuation of which can jeopardise the company’s competitiveness. Russian machine-building enterprises are currently facing an acute shortage of investment funds, and the payback period for investments in the purchase of expensive equipment threatens to extend indefinitely.

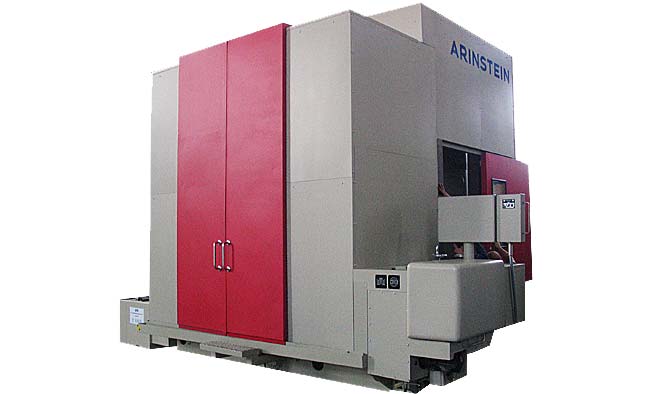

Faced with such conditions, the machine tool company ARINSTEIN, a supplier of cutting-edge technologies and machining equipment from Europe, has developed a special offer for the repair and modernisation of machine tools.

In the last 14 years, ARINSTEIN has carried out over 40 different retrofit projects on various machines, including machines from Heckert, Heid, Georg Fischer, Niles, Maho and many others.

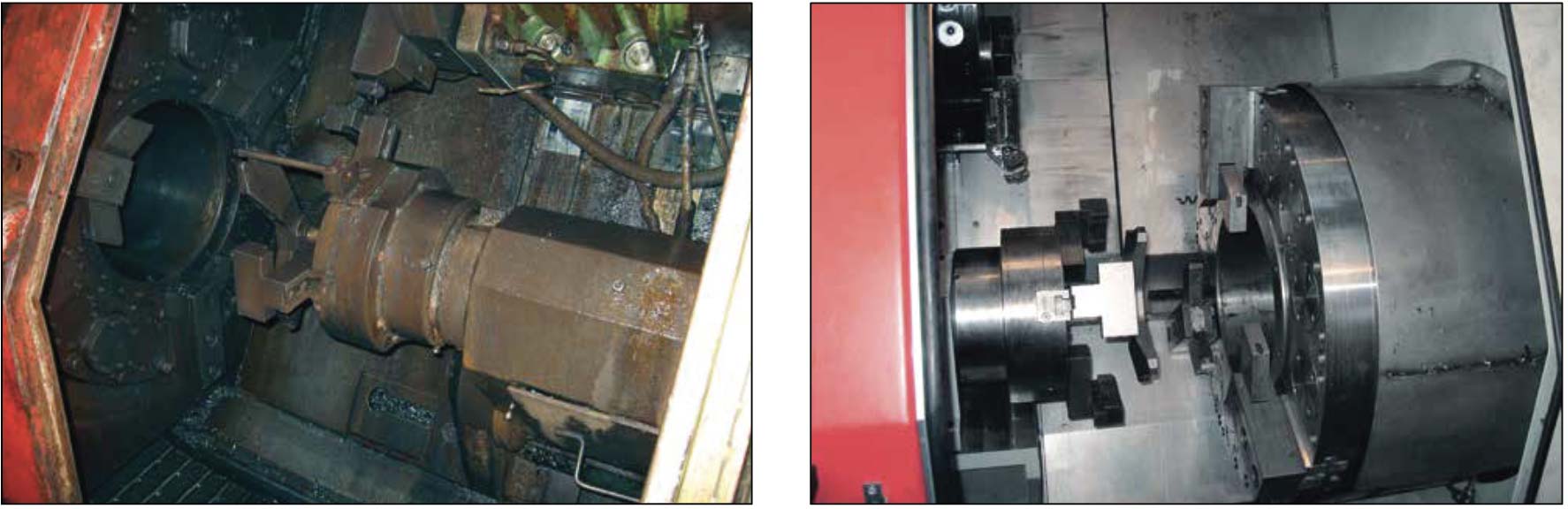

All overhaul and modernisation work is carried out in Germany at the Arinstein production site in Berlin. When machine tool equipment is modernised, more than 75% of its units are replaced: CNC system, electrical equipment, drives, hydraulic and pneumatic systems, bearings, ball screws and rubber goods. At the same time, upgrade costs often represent 40-60% of the cost of a comparable new machine.

Many companies offer a shortened version of modernisation – replacement of the CNC system and electrical automation. However, practice shows that components that are not replaced with new ones, such as hydraulic hoses and hydro valves, have a limited lifetime and may need to be replaced in the near future. Another disadvantage of such modernisation is the lack of spare parts, many of which are no longer available.

When cooperating with customers, we offer modernisation only on the basis of modern components from leading manufacturers (Siemens, Rexroth, Parker, Hawe, Lapp, Igus, RSF, Sauter, Flender, etc.) with obligatory overhaul of the equipment. The starting point for the cooperation with the customer is a specification sheet in which requirements and desired results for the overhaul and modernisation are defined. The ARINSTEIN specialists assess the technical condition of the plant and agree the scope and costs of the work with the customer.

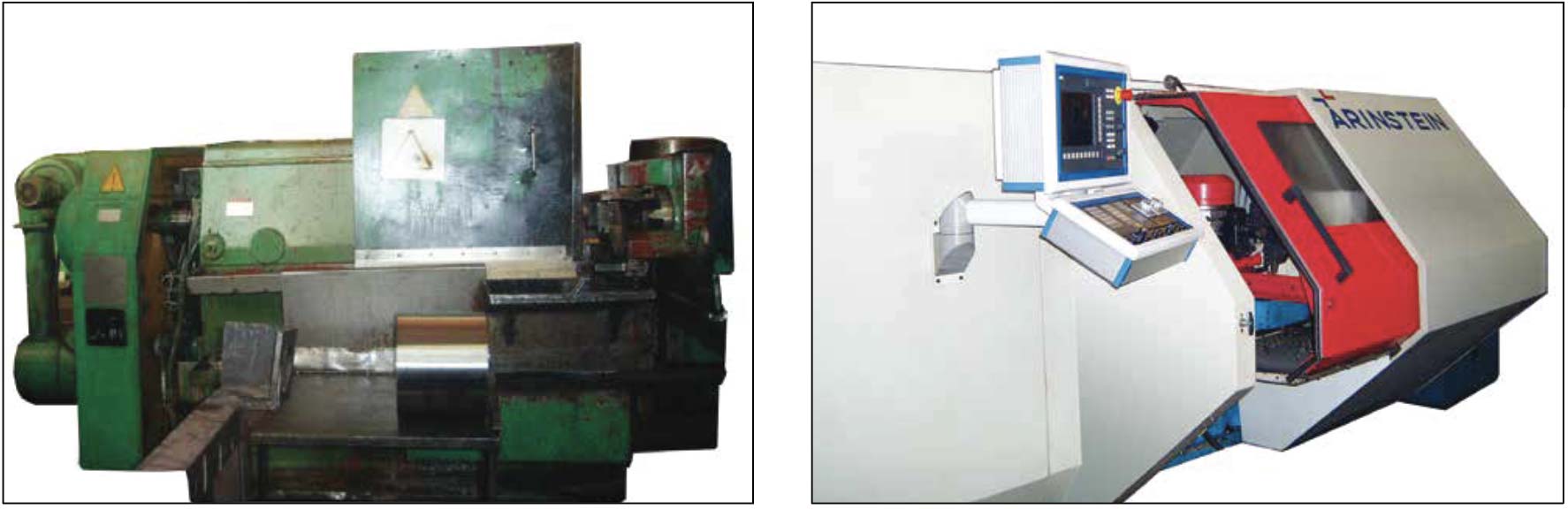

- Replacement of the outdated software control system with a modern Sinumerik 840D control system in modular design with integrated S7-300 control;

- Replacement of the main drive and the feed drive with Siemens – Simodrive 611;

- Replacement of electrical equipment, control cabinet and control panel with modern equipment;

- Additional control via portable console;

- Replacement of hydraulic, pneumatic and lubrication equipment with modern equipment;

- Turret by Sauter;

- Rotary chuck from Röhm;

- Arm drive of the loading device with planetary gear by Harmonic Drive (C-axis);

- Reinforced chip conveyor with high chip discharge height into the container;

- Hermetically sealed cabin.

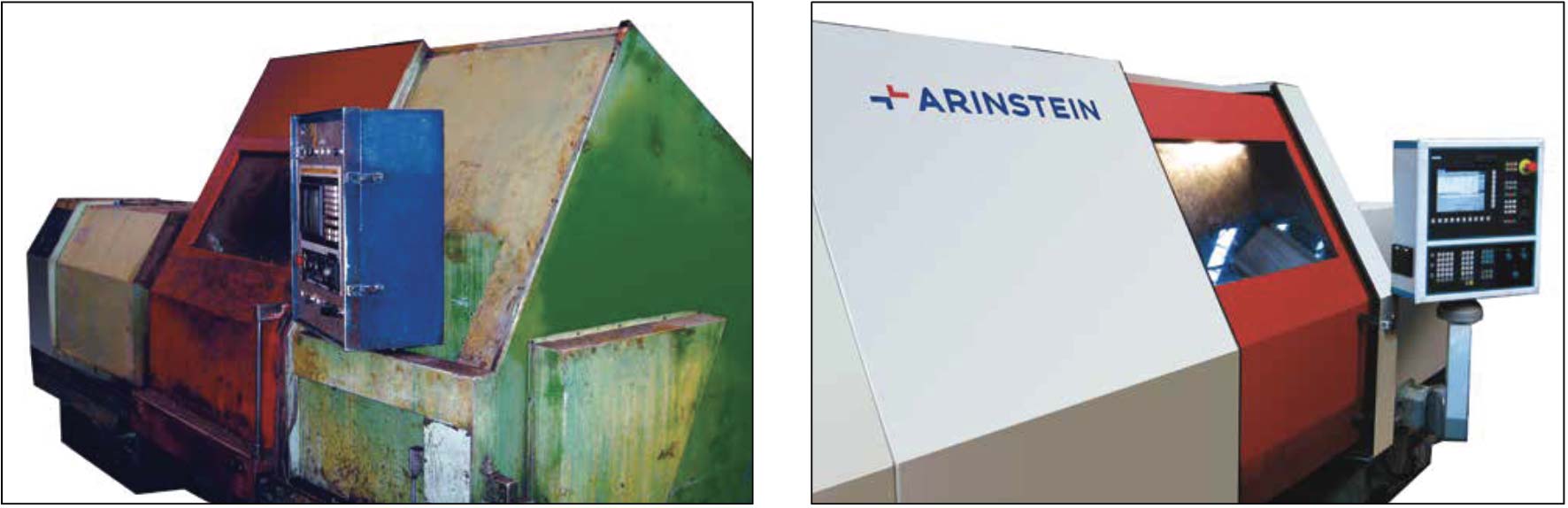

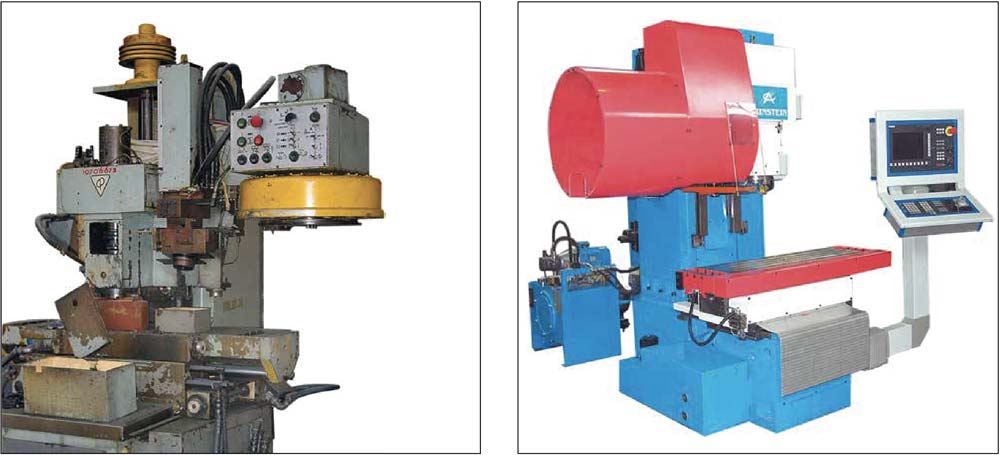

- Replacement of the outdated software control system with a modern system with Simatis S7-300 controller and OP 177B operating panel;

- Installation of Siemens drives – Simodrive 611U;

- Replacement of electrical equipment, control cabinet and control panel with modern equipment;

- Replacement of hydraulic, pneumatic and lubrication equipment with modern equipment;

- Sealed cabin.

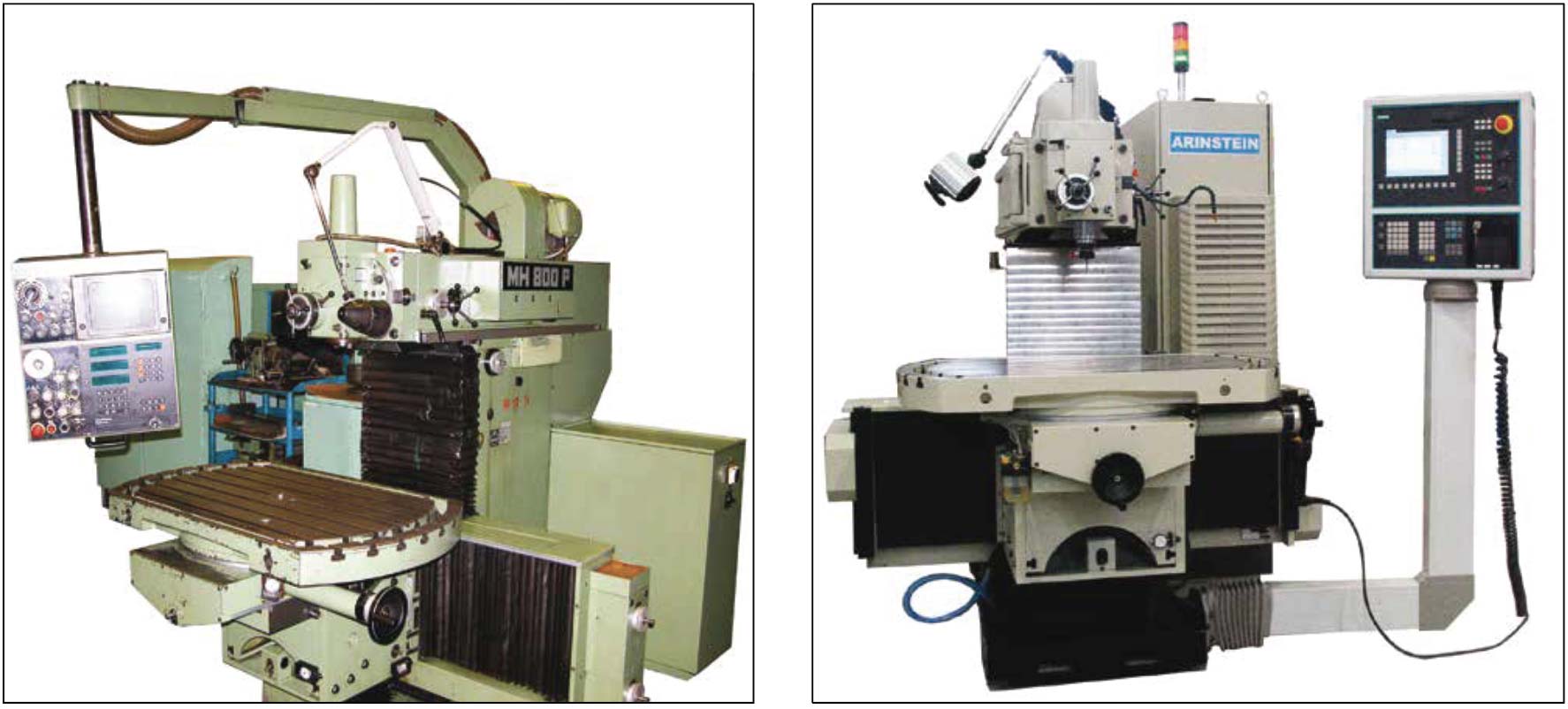

- Replacement of the outdated software control with a modern Sinumerik 802D control;

- Replacement of the main and feed drives with Siemens – Simodrive 611UE;

- Replacement of the electrical equipment, control cabinet and control panel with modern equipment;

- Replacement of hydraulic, pneumatic and lubrication equipment with modern equipment;

- Replacement of horizontal and vertical head spindles;

- Installation of ball screws (recirculating ball screws) on axes X,Y,Z;

- Installation of a new cable chain ( caterpillar ) for electrical and hydraulic routes to the moving units;

- Siemens electric motors for axes X,Y,Z;

- Hydraulic cylinders for unloading the ball screws of the Y-axis;

- Installation of RSF linear sensors;

- Portable console for manual control of axes and machine spindle rotation.