TRAINING MACHINES – MINIMACHINES FOR EDUCATION

Mathematics and Physics appear to be exact sciences that do not attract enough of students’ interest. The problem results from many factors including teachers’ limited capability to give examples of practical application of the above mentioned disciplines to technology. Arinstein Machine tool Company has developed a new training product allowing to demonstrate CNC turning and milling machines functioning and to reveal complex and amazing world of technology by means of PC.

We hope that this training will provide young specialists with new prospects and opportunities.

Training Purposes:

- To learn turning and milling machines basic units: CNC control, standard spindle assembly, linear guideway, step motors, ball screw drives and cutting tool;

- To learn field of industrial application of turning and milling machines;

- To demonstrate technical performance and capacities of turning and milling machines;

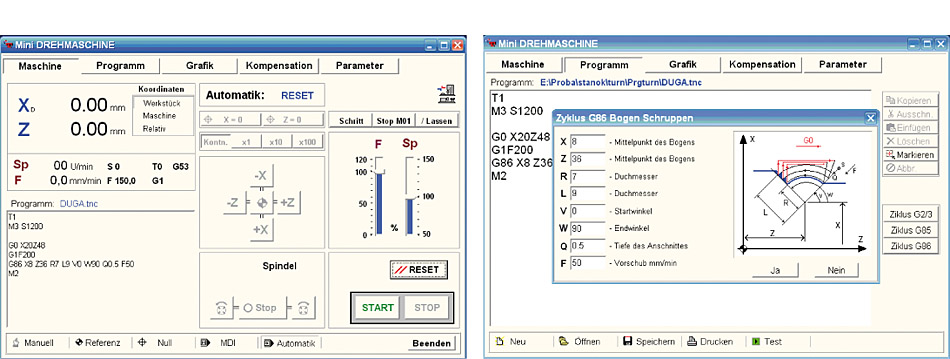

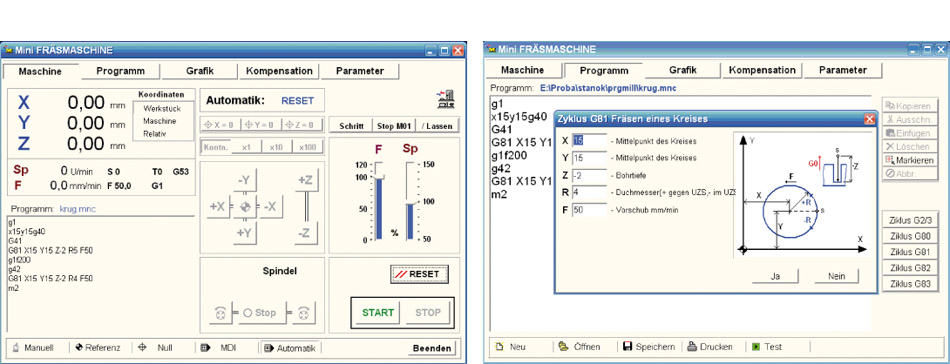

- To learn working models of PC-based machine control;

- To learn ISO-programming for work pieces processing;

- To familiarize with PC application methods in order to control machines and units operation.

Technology is interesting!

Mathematics and physics are the exact sciences that are currently of little interest to students. The reason for this is many factors, one of which is the limited opportunities for teachers to show the practical application of these subjects in engineering through examples. Machine tool manufacturer Arinstein has developed a new training product that is a PC-based demonstration of the lathe and milling machine, showing the complex and fascinating world of engineering. We hope to open up new perspectives and opportunities for young people.

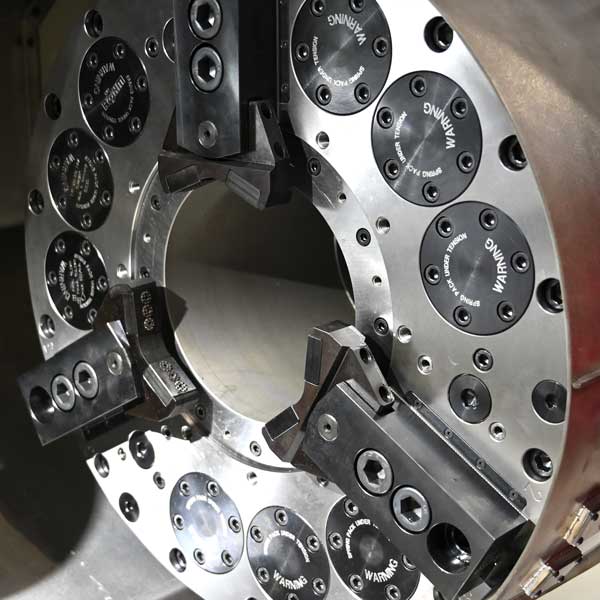

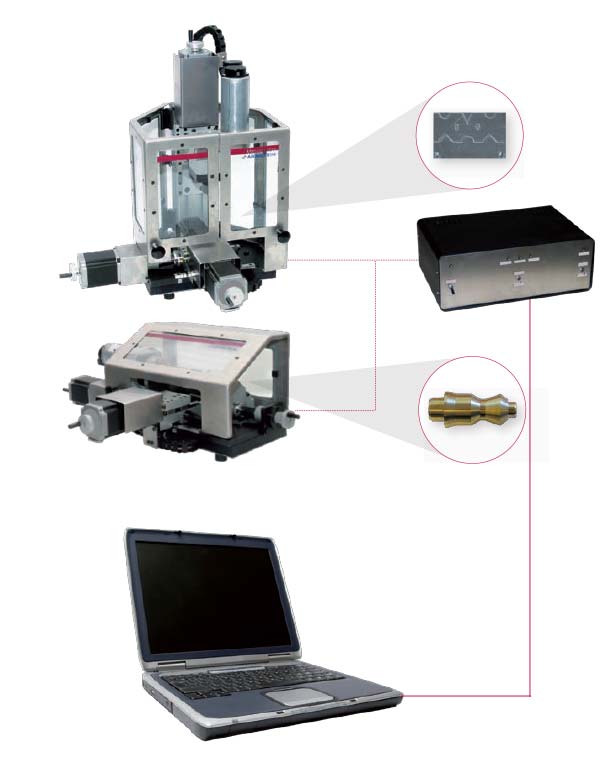

„Arinstein MiniTurn 45“ CNC turning machine is a PC-controlled two-axis desktop turning machine. Its design and performance correspond to industrial standards. The machine is assigned for turning operation of workpieces such as „fl ange“ or „roller“, composite surfaces such as „ball stud“ as well as for internal drilling.

Workpiece is clamped by a three-jaw chuck.

Standard machine (with a three-jaw chuck):

- Two-axis turning machine with a three-jaw chuck;

- Double-bitted toolholder;

- Tailstock with a sliding sleeve;

- Tailstock rotating center;

- Power supply and control unit;

- Set of cutters;

- Set of drills;

- Set of sliding sleeve collets;

- Cutting tools;

- Conversational languages: German, English, Russian, French and Spanish.

| TECHNICAL DATA | |

| Parameters | |

| X axis travel | 85 mm |

| Z axis travel | 85 mm |

| Y axis travel | 70 mm |

| Max. length of workpiece | 85 mm |

| Max. diameter of workpiece clamped by three-jaw chuck | 1,8…56 / 12…65 mm |

| Three-jaw chuck diameter | 50 mm |

| Spindle bearing inner diameter | 8 mm |

| Range of spindle speed | 120…1235 rpm |

| Max. spindle torque value | 0,44 Nm |

| X, Z axes positioning accuracy | 0,01 mm |

| Number of tool holder slots | 2 |

| Tool cross-cut | 5 х 5 (10 х 5) mm |

| Power sources | |

| Voltage | 220 V; 50/60 Hz |

| Electrical power supply | 300 Watt |

| Maximum current intensity | 2 А |

| Allowable ambient temperature | +10 °C … +35 °C |

| Machine size | |

| W x L x H | 408 х 410 х 470 mm |

| Mass of the machine | 16 kg |

| Computer Components | |

| IBM or IBM-compatible processor | Pentium 2000MHz |

| HDD | 10 Gb |

| Disk Drive | CD-R |

| Operating System | Win 98, Win 2000, XP и выше |

| Ports | Port LTP-1 и Port COM-1 |

„Arinstein MiniMill 45“ CNC milling machine is a PC-controlled three-axis desktop milling machine. Its design and performance correspond to industrial standards. The machine is assigned for milling and drilling operations.

Standard machine:

- Three-axis milling machine with a collet chuck;

- Power supply and control unit;

- Set of drills;

- Set of milling cutters;

- Set of milling spindle collets;

- Cutting tools;

- Conversational languages: German, English, Russian, French and Spanish.

| TECHNICAL DATA | |

| Parameters | |

| X axis travel | 85 mm |

| Z axis travel | 85 mm |

| Y axis travel | 70 mm |

| Distance between spindle undersurface and worktable | 95 mm |

| Table dimensions (L x W) | 58 x 44 mm |

| Max. workpiece weight | 0,2 kg |

| Workpiece clamping with four М4,screws, Distance between the holes | 55 mm |

| Collet tool locking type (Schaublin) | DIN 6499B ESX16 |

| Tool clamping | manual |

| Range of spindle speed | 120…1235 rpm |

| Max. spindle torque value | 0,44 Nm |

| X, Z axes positioning accuracy | 0,01 mm |

| Power sources | |

| Voltage | 220 V; 50/60 Hz |

| Electrical power supply | 300 Watt |

| Maximum current intensity | 2 А |

| Allowable ambient temperature | +10 °C … +35 °C |

| Machine size | |

| W x L x H | 408 х 410 х 470 mm |

| Mass of the machine | 16 kg |

| Computer Components | |

| IBM or IBM-compatible processor | Pentium 2000MHz |

| HDD | 10 Gb |

| Disk Drive | CD-R |

| Operating System | Win 98, Win 2000, XP и выше |

| Ports | Port LTP-1 и Port COM-1 |