ARINSTEIN MACHINES

INFORMATION AND REFERENCES

Requirements to matelaworking machine dramatically changed in the last decades. Following parameters have reached primary importance:

- Functional versatility, precision and reliability;

- Convenient and easy operation and maintenance;

- High productivity;

- Energy efficiency;

- Connectivity;

- Reasonable prices.

The new generation lathes A500 by Arinstein features all the above parameters.

Ergonomical properties of the machine are defined by the bed with the reach-over carriage; precision of travel is ensured by linear type guidelines; technological capacities of the machine are increased thanks to the turret with driven tools. The machine’s state-of-the-art CNC is suitable for solving complex technical tasks.

A 500 series is intended for high precision turning and milling of flange and roll type work-pieces, complex surfaces, e.g., knuckle pins, for tapping and threading, for milling grooves and profiles, and also for drilling holes beyond the center line of the work-piece.

Workpieces made of construction steel, alloyed and tool grades of steel, pig iron, non-ferrous and light alloys can be handled on these lathes. A 500 series are intended for manufacturing small lots and series.

Components

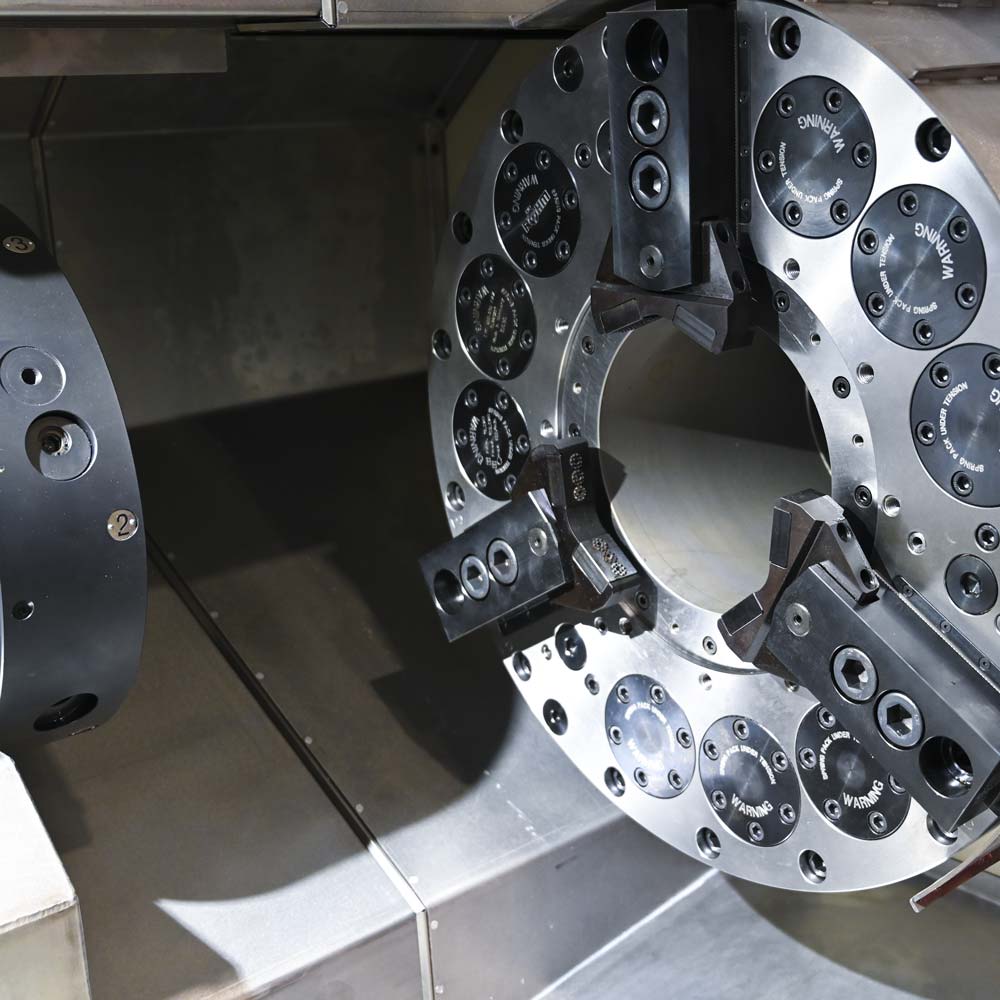

Turret head of Baruffaldi, Sauter or DuplomaticEfficient power transfer through a compact design;

- Maximum spindle speed 4000 rpm;

- High turning accuracy.

- CNC controls of Fanuc or Siemens

High machining accuracy;

- 3D visualization of the machining process;

- Network operation;

- Use of ShopTurn software by Siemens;

- TFT displays from 10,4″ to 17″ (Siemens / Fanuc);

- Connectivity by LAN / WLAN / USB.

Electric cabinets are air-conditioned (Rittal) and fitted out with components by such well-known suppliers as Siemens, Baluff, Kloeckner-Mueller, etc.

Design Features

- The bed is a welded steel construction that is filled with special sand so as to provide more rigidity against vibration and sound absorption, and also to reduce thermal deformations.

- Moveable units are provided with linear roller-type guidelines (similar to THK) that ensure high precision of traveling and longer lifetime of the lathe.

- Feed drives include ball screws and digital AC motors supplied by Siemens.

- The headstock supplied by EMCO, Austria, is a cast case with ribbed surface so as to reduce thermal deformations; inside the headstock a spindle runs on high precision roll bearings.

- Angle of the spindle is controlled by means of a special sensor.

- The 2nd spindle (optional) is a motor spindle by Siemens, which is installed on movable carriage instead of the tailstock.

- All the movable components are located inside the cabin so as to ensure safe operation of the machine; guidelines of the movable units are protected against chips and emulsion.

- Thanks to the slanted position of the reach-over carriage, chips are dropped to the conveyor located in the front part of the machine.

- The hydraulic system is integrated into one module which includes a tank with an inbuilt gear pump, an air heat exchanger, distribution, control and measuring devices.

- The control console is equipped with TFT up to 17″, keyboard and handwheel.

- The CNC Sinumerik 840 Dsl is compatible with the programming standards of DIN/ISO.

Specification and main parameters of the CNC

Linear and circular interpolation

Data editing for program input and modification

Graphical testing of part programs

Radius and length compensation

Cycles of deep drilling, tapping, groove milling, selection and contouring of rectangular, round and any other pockets

Mirror machining and Scaling ratio

Program rotation and shift

Axis travel alignment by means of potentiometer, 0-120%

Spindle speed alignment by means of potentiometer, 50-120%

| Company | Country |

|---|---|

| EUROPE | |

| Akcan Makine Sanayii Ltd. Sti. | Turkey |

| Ambold Pressen & Maschinenbau GmbH | Germany |

| ARO Schweisstechnologien GmbH | Germany |

| Emtec Ltd. | Great Britain |

| Forelli Pietro SpA | Italy |

| FPM Srl. | Italy |

| John Deere Werke | Germany |

| Mannesmann Demag GmbH | Germany |

| Marcels Maschinen AG | Switzerland |

| Maskin-Importen ApS | Denmark |

| Metalexport Ltd | Poland |

| NKMZ | Ukraine |

| RD Machine Outils | France |

| San Miguel S.L. | Spain |

| Siegfried Jacob Metallwerke | Germany |

| AMERICA | |

| Power Engineering & Manufacturing, Inc. | USA |

| Stan Canada Inc. | Kanada |

| Supfina Machine Co., Inc. | USA |

| The Gear Works | USA |

| AFRICA | |

| Piston Trading LLC | Emirates |

| Hestico Ltd. | SA |

| ASIA | |

| Lianpad Co Ltd | India |

| Mega Motors Company | Iran |

| VIT Co. Ltd | Vietnam |

| AUSTRALIA | |

| GE Aircraft Engines | Australia |

| MODIFICATION | А500.1 | А500.2 | А500.3 |

| Swing over bed | 570 mm | 570 mm | 570 mm |

| Maximum turning diameter (for a length 170 mm) | 520 mm | 520 mm | 520 mm |

| Swing over cross slide | 375 mm | 375 mm | 375 mm |

| Distance between centers | 1000/1500/2000 mm | 1000/1500/2000 mm | 2000 mm |

| X-axis travel | 310 mm | 310 mm | 310 mm |

| Z-axis travel | 1000/1500/2000 mm | 1000/1500/2000 mm | 1000 mm |

| Y-axis travel (option) | ±50 mm | ±50 mm | ±50 mm |

| Maximum part length | 1000/1500/2000 mm | 900/1400/1900 mm | 1900 mm |

| Maximum workpiece weight flying | 250 kg | 250 kg | 250 kg |

| Maximum workpiece weight between centers | 600/800/1000 mm | 600/800/1000 mm | 900 mm |

| Distance between chuck end-face and center of gravity | – | 175 mm | 175 mm |

| HEADSTOCK | |||

| Spindle nose according to DIN 55026 | A2-8 | A2-8 | A2-8 |

| Chuck diameter | 315 mm | 315 mm | 315 mm |

| Spindle bore | 103 mm | 103 mm | 103 mm |

| Hole in draw tube | 90 mm | 90 mm | 90 mm |

| Speed range | 40… 3000 rpm | 40… 3000 rpm | 40… 3000 rpm |

| MAIN DRIVE | |||

| AC-motor | Fanuc (Siemens) | Fanuc (Siemens) | Fanuc (Siemens) |

| Power S1/S6 | 30/37 (28/43) kW | 30/37 (28/43) kW | 30/37 (28/43) kW |

| ZF double reduction gear (1:4) (option) | – | – | – |

| Maximum torque on spindle (without ZF-reducer) | 500/620 (535/800) Nm | 500/620 (535/800) Nm | 500/620 (535/800) Nm |

| Maximum torque on spindle (with ZF-reducer) | 1500(1800) Nm | 1500(1800) Nm | 1500(1800) Nm |

| FEED DRIVE SYSTEM | |||

| Maximum feed force in X and Y axis | 7500 N | 7500 N | 7500 N |

| Maximum feed force in Z axis | 11000 N | 11000 N | 11000 N |

| Rapid traverse | 20 m/min | 20 m/min | 20 m/min |

| TOOL TURRET | |||

| Number of tool stations/ including driven (option) | 12/12 | 12/12 | 12/12 |

| Tool shank according to DIN 69880 | VDI 40 | VDI 40 | VDI 40 |

| Maximum torque on tool (Fanuc/Siemens) | 43/34 Nm | 43/34 Nm | 43/34 Nm |

| Maximum power (Fanuc/Siemens) | 5,5/12,7 kW | 5,5/12,7 kW | 5,5/12,7 kW |

| Maximum rotary speed (Fanuc/Siemens) | 4000/3600 rpm | 4000/3600 rpm | 4000/3600 rpm |

| C-AXIS (option) | |||

| Minimum spindle indexing angle | 0,01 degrees | 0,01 degrees | 0,01 degrees |

| Maximum torque (Fanuc/Siemens) | 500 Nm | 500 Nm | 500 Nm |

| Maximum rotary speed | 80 rpm | 80 rpm | 80 rpm |

| TAILSTOCK | |||

| Taper hole | MK5 | MK5 | MK5 |

| Maximum application force, (tailstock without sleeve) | 11000 N | 11000 N | 11000 N |

| Sleeve diameter/stroke | 100/140 mm | 100/140 mm | 100/140 mm |

| Axial/radial sleeve load | 5000/7500 N | 5000/7500 N | 5000/7500 N |

| STEADY REST (option) | |||

| Gripping diameter | 8… 105/15… 170/35… 250 mm | 8… 105/15… 170/35… 250 mm | 8… 105/15… 170/35… 250 mm |

| DIMENSIONS | |||

| Height, width | 2360/2230 mm | 2360/2230 mm | 2360/2230 mm |

| Length with chip conveyor | 5360/5960/6550 mm | 5360/5960/6550 mm | 6550 mm |

| Weight with chip conveyor | 11000/13000/15000 kg | 11000/13000/15000 kg | 15000 kg |